Introduction

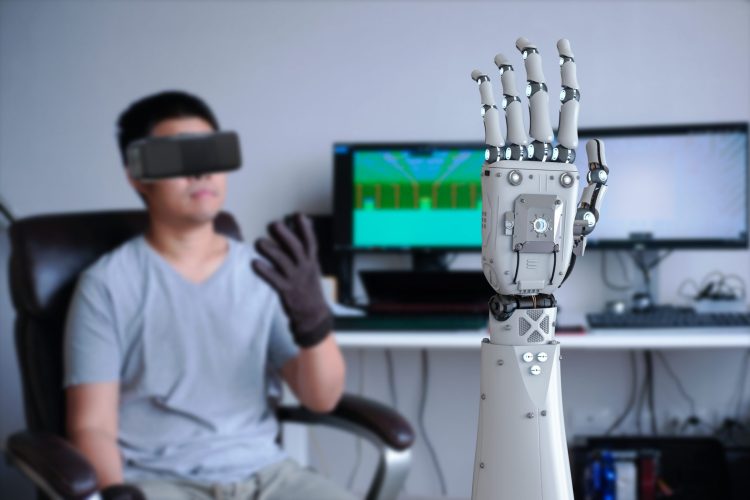

As robotics technology continues to advance, the demand for highly flexible, durable, and strong robots is becoming more pronounced. In applications ranging from surgical robots and robotic prosthetics to industrial robots and autonomous vehicles, robots must be able to perform tasks that require a combination of both flexibility and strength.

However, achieving this balance is no easy feat. Flexibility refers to the ability of a robot to adapt to various tasks and environments, such as manipulating delicate objects or navigating through tight spaces. Strength, on the other hand, is essential for tasks requiring significant force, such as lifting, carrying, or manipulating heavy items. Durability is another critical factor, as robots must be able to withstand wear and tear over time, especially in challenging environments.

The challenge lies in the fact that flexibility, strength, and durability are often at odds with one another. Materials and design choices that enhance flexibility may compromise strength and vice versa. This article delves into the key challenges faced by engineers in achieving the ideal balance between flexibility, strength, and durability in robot design. We will explore the materials, actuation mechanisms, and design approaches that hold promise for addressing this technological dilemma.

The Trade-Off Between Flexibility and Strength

1. Understanding Flexibility in Robots

Flexibility in robots refers to the ability to perform a variety of motions and tasks, often by adjusting to changes in the environment or the objects being manipulated. Flexible robots are capable of performing intricate operations, such as:

- Grasping delicate objects with varying shapes and sizes.

- Adapting to different terrains or workspace conditions.

- Interacting with humans in collaborative settings (e.g., cobots or collaborative robots).

Flexibility is typically achieved by using soft materials, biomimetic structures, and multi-jointed limbs that can bend and stretch. Soft robots, inspired by biological organisms such as octopuses and worms, often rely on deformable materials that allow them to change shape and adapt to tasks.

However, flexibility often comes at the cost of strength. Materials that are soft and flexible may not possess the structural integrity required to handle heavy loads or exert significant force.

2. Understanding Strength in Robots

Strength, on the other hand, refers to the ability of a robot to exert large amounts of force while maintaining structural stability. Robots used in industries like automotive manufacturing, construction, and logistics need to be strong enough to lift heavy components, move large objects, and perform demanding physical tasks.

To achieve strength, traditional robots often use rigid materials, such as metals, carbon fibers, or hard plastics. These materials provide the necessary structural support to handle heavy lifting, precise movements, and demanding environments. However, rigidity and strength come at the cost of flexibility. Rigid robots are often bulky and cannot adapt as easily to unpredictable or constrained environments.

The challenge, therefore, lies in combining these seemingly contradictory properties — achieving strength without sacrificing flexibility, and vice versa.

Key Materials for Enhancing Flexibility, Strength, and Durability

1. Soft and Composite Materials

Recent advancements in materials science have led to the development of soft materials and composite structures that offer both flexibility and strength. By combining soft, elastomeric materials with reinforcing fibers, manufacturers are creating robots that can adapt to their environment while still handling heavy loads. Examples include:

- Silicone-based elastomers: Used for their flexibility, these materials are often combined with reinforcing materials like carbon fibers or other composites to add strength.

- Shape-memory alloys (SMAs): Materials that return to a pre-set shape when heated, allowing for both flexibility and force transmission when actuated.

- Fiber-reinforced polymers (FRPs): These materials provide high strength and stiffness while maintaining a lightweight, flexible structure. FRPs can be molded into different shapes, making them ideal for robotic arms or exoskeletons.

Smart materials such as piezoelectric and magnetorheological materials are also being explored for their ability to adapt to different forces and environmental conditions, providing a novel way of balancing flexibility and strength.

2. Exoskeletons and Soft Robotics

The rise of soft robotics has led to new designs that mimic the flexibility and adaptability of biological organisms. By combining soft materials with actuation systems, engineers can create robots that can morph in shape while maintaining sufficient strength for specific tasks.

For example, robotic exoskeletons used in rehabilitation are made with flexible materials that can conform to the user’s body. At the same time, these exoskeletons need to provide enough strength to assist with movement and lifting. Soft actuators such as pneumatic muscles, hydraulic actuators, and artificial muscles can produce the necessary force without compromising flexibility.

Similarly, soft robots like soft grippers are used to handle fragile objects by adjusting their grip force and shape based on the object’s dimensions. These systems allow robots to perform highly dexterous tasks while ensuring safe interaction with delicate items.

Advanced Actuation Mechanisms

1. Pneumatic and Hydraulic Actuators

One of the most promising solutions for enhancing both flexibility and strength is the use of pneumatic or hydraulic actuators. These actuators can provide high power density and controlled, smooth motions, making them ideal for soft robots or robots that need to adapt to different loads.

- Pneumatic actuators use compressed air to inflate chambers within the robot, causing movement. These actuators are flexible and can be scaled to produce a variety of motions and forces, depending on the needs of the robot.

- Hydraulic actuators, which rely on the pressurized flow of liquids, can generate much more significant force compared to pneumatic actuators. These actuators are particularly useful in heavy-duty robotic applications, such as industrial robots used for lifting and assembly.

Both types of actuators offer flexibility while maintaining the ability to generate substantial strength. The challenge lies in optimizing the actuation system for both force generation and controlled movement, especially for tasks requiring high precision.

2. Shape Memory Alloys (SMAs)

Shape-memory alloys are another actuation technology that can provide both flexibility and strength. These materials change shape in response to environmental stimuli such as temperature, offering a unique mechanism for motion. When heated, SMAs can return to their original shape, allowing robots to perform complex, adaptive movements.

In addition to their flexibility, SMAs offer a high force-to-weight ratio, making them ideal for lightweight robots that still need to handle substantial loads.

3. Electroactive Polymers (EAPs)

Electroactive polymers are materials that change shape when subjected to an electric field. EAPs are considered one of the most promising actuators for soft robots due to their lightweight, flexible, and low-energy properties. These polymers can mimic biological muscles, enabling highly flexible and adaptive movements while still offering the strength needed for specific tasks.

EAPs are particularly valuable for creating robots that interact with humans or delicate objects, where flexibility is essential for safe, efficient operation. However, challenges remain in terms of scaling and stability under prolonged use.

Engineering Design Solutions

1. Modular and Hybrid Robot Designs

One potential solution to balancing flexibility, strength, and durability is the use of modular and hybrid robot designs. In these systems, robots consist of multiple interchangeable parts that can be optimized for specific tasks. For example, a robot may have soft actuators for delicate operations and rigid actuators for heavy-duty tasks. This approach allows for greater flexibility in design and ensures that each part of the robot can be tailored to its specific function.

Hybrid robots, which combine soft and rigid materials, are particularly useful for applications that require both precision and strength. For instance, a soft robot arm may have a rigid skeleton that provides structural support while the outer layer remains flexible for tasks like gripping and moving delicate objects.

2. Bio-Inspired Designs

Roboticists are increasingly turning to bio-inspired designs to address the challenge of balancing flexibility with strength. By mimicking biological organisms, engineers can create robots that are both adaptable and resilient. For example:

- Octopus-inspired robots use soft, flexible arms that can manipulate objects and move with remarkable dexterity. These robots can be designed to mimic the octopus’s ability to manipulate objects with precision, which is crucial for tasks like assembly and disassembly in constrained spaces.

- Exoskeletal designs that incorporate flexible joints and articulating parts allow robots to mimic the movements of animals like insects or vertebrates, providing both strength and agility.

By leveraging nature’s solutions to these design challenges, engineers are developing robots that are more adaptable, resilient, and capable of performing tasks that require a balance of flexibility and strength.

Conclusion

The challenge of designing robots that are both flexible and strong while maintaining durability is a complex and multi-faceted problem. Engineers are increasingly relying on innovative materials, actuation mechanisms, and design approaches to address this challenge. Advances in soft robotics, composite materials, and bio-inspired designs are pushing the boundaries of what robots can achieve in terms of performance and versatility.

As we continue to explore new technologies and refine robot design, the ability to create robots that seamlessly combine flexibility, strength, and durability will be essential for a wide range of applications, from medical robots and assistive devices to industrial automation and search-and-rescue missions.

By overcoming the trade-offs between flexibility and strength, the next generation of robots will be able to operate in more dynamic, diverse environments, handle increasingly complex tasks, and interact with humans and objects in safer, more efficient ways. The future of robotics holds enormous potential, and achieving this balance will be a key driver in realizing that potential.