Introduction

Soft robotics is an emerging field that focuses on developing robots that are designed to mimic the flexibility and adaptability of natural organisms. Unlike traditional rigid robots made from metal or hard materials, soft robots are constructed from flexible, deformable materials that allow them to perform tasks with greater versatility and dexterity. By drawing inspiration from nature—such as octopuses, worms, and other soft-bodied animals—scientists and engineers are pushing the boundaries of what robots can do in a wide variety of applications, from medical surgery to manufacturing and even space exploration.

Soft robotics offers a remarkable departure from traditional robotics, where machines often struggle with tasks requiring a high degree of dexterity and sensitivity. The unique abilities of soft robots to squeeze, stretch, and bend open up possibilities in environments and tasks where rigid robots would be ineffective or impossible to use. For instance, they could be used to explore delicate environments like the human body, or work safely alongside humans in collaborative settings, making them a promising technology for industries such as healthcare, agriculture, and logistics.

This article delves into the field of soft robotics, exploring its scientific foundations, current advancements, applications, and future potential. Through a detailed examination of the design principles and materials used in soft robots, as well as their bio-inspired capabilities, we aim to highlight the incredible potential of this rapidly advancing field.

What Are Soft Robots?

1. The Concept of Soft Robotics

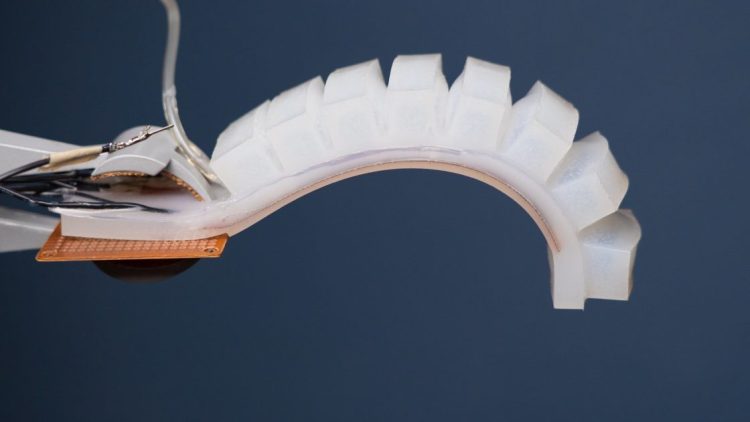

Soft robotics refers to a subset of robotics that emphasizes the design and use of robots made from soft, flexible materials that can deform and move in ways similar to natural organisms. Unlike traditional robots with rigid, metallic structures, soft robots typically utilize elastomers, silicones, gels, and other compliant materials to achieve motion. These robots are highly adaptable and can perform a range of movements that traditional robots with hard bodies cannot replicate, such as bending, stretching, and squeezing.

The idea behind soft robotics is to create robots that can interact more naturally with their environment, offering significant advantages in areas where traditional rigid robots fall short. Bio-inspired design principles play a critical role in the development of soft robots, drawing from the biomechanics of soft-bodied animals like octopuses, squids, and earthworms, which exhibit remarkable flexibility and dexterity.

2. The Role of Bio-Inspired Engineering

The study of biomimicry—the design and production of materials, structures, and systems that are modeled on biological organisms—is a foundational aspect of soft robotics. Nature has optimized the design of many creatures for specific tasks, such as soft-bodied animals that are capable of squeezing through tight spaces or flexible limbs that can grasp and manipulate delicate objects. By analyzing these organisms and their behaviors, engineers can develop robots that perform similarly.

For example, the octopus is one of the most studied soft-bodied animals due to its exceptional manipulation and control capabilities, despite having no rigid bones. An octopus can squeeze through tiny openings and adapt its body to various shapes and sizes. Soft robots inspired by the octopus are able to manipulate objects with dexterity and navigate complex, unstructured environments.

Design Principles of Soft Robotics

The design of soft robots involves a multidisciplinary approach that combines insights from materials science, mechanical engineering, biomechanics, and control systems. There are several key principles that define soft robotics:

1. Flexibility and Deformability

Soft robots rely on the ability to deform in response to external forces, enabling them to take on various shapes and adapt to different environments. This ability is critical for tasks that require highly adaptable movement, such as navigating confined spaces or performing delicate operations in areas where precision and flexibility are required.

2. Compliant Materials

One of the defining characteristics of soft robots is the use of compliant materials that allow for controlled deformation. These materials, such as silicone, elastomers, and hydrogels, provide the necessary flexibility and softness for a robot to move in an organic way. By embedding sensors or actuators within these materials, soft robots can achieve complex movements and responsive actions, mimicking the capabilities of soft organisms in nature.

3. Actuation Mechanisms

Actuators are the components that enable a robot to move or change shape. In soft robotics, the actuation mechanism often involves pneumatic, hydraulic, or electroactive materials that can change shape in response to external stimuli. For example:

- Pneumatic actuators use pressurized air to inflate or deflate parts of the robot, allowing it to move or change shape. These actuators can be used in soft robots to simulate the muscle contractions of animals.

- Hydraulic actuators use liquid pressure to create movement, enabling more precise control over the robot’s shape and motion.

- Electroactive materials change shape when exposed to an electric field, offering the advantage of being lightweight and energy-efficient.

4. Sensors and Feedback Systems

Soft robots rely heavily on sensor networks to provide real-time feedback on their environment and adjust their actions accordingly. These sensors can detect parameters such as pressure, temperature, position, and force. For instance, a soft robot designed for medical applications might include sensors that monitor the amount of pressure it is applying to human tissue during surgery to avoid causing harm. Soft sensors, made from flexible materials, are integrated into the structure of the robot, allowing it to sense and respond to its surroundings with precision.

Applications of Soft Robotics

Soft robotics has already begun to revolutionize several industries by offering solutions to problems that were previously difficult or impossible to address with traditional rigid robots. Below are some of the most promising applications for soft robots:

1. Healthcare and Medicine

One of the most exciting applications of soft robotics is in the medical field. Soft robots have the potential to dramatically improve surgical procedures, patient care, and rehabilitation. Their flexibility and ability to deform make them ideal for performing minimally invasive surgeries, where traditional robotic systems might be too rigid or bulky.

- Soft surgical robots: Soft robots can be used in surgical tools that are capable of navigating tight or irregular anatomical structures, such as the digestive tract or blood vessels, with much greater flexibility and reduced risk of tissue damage.

- Medical prosthetics: Bio-inspired soft robots can be used to create prosthetic limbs that mimic the functionality and dexterity of natural limbs. These prosthetics could provide users with enhanced comfort and better functionality in comparison to traditional rigid prosthetics.

- Rehabilitation: Soft robots can assist in physical rehabilitation by providing gentle, adaptable assistance to patients recovering from injuries. These robots can simulate human-like movement, providing more effective therapy with less discomfort.

2. Agriculture

In agriculture, soft robotics can be employed to carry out tasks that require precision and care, such as picking fruits or harvesting crops. Soft robots designed for agricultural applications can gently handle delicate plants and fruits without causing damage, mimicking the way animals might interact with their environment.

- Crop harvesting: Soft robots can help reduce labor costs and improve the efficiency of harvesting by automating tasks like fruit picking. These robots can be designed to handle delicate produce, such as tomatoes or apples, without bruising or damaging them.

- Weeding and soil care: Soft robots can also be used for weeding or performing soil maintenance tasks. These robots can navigate through fields with agility, performing tasks like soil tilling or weed removal without disturbing the crops.

3. Search and Rescue Operations

Soft robots have significant potential in search and rescue operations, especially in environments that are too dangerous or difficult for humans to navigate. Soft robots’ ability to squeeze through small openings and their adaptability make them ideal for rescue missions in collapsed buildings, caves, or under rubble.

- Disaster response: Soft robots equipped with sensors and actuators can navigate through debris and debris-filled environments, searching for survivors or providing critical assistance in hazardous situations.

4. Exploration and Underwater Robotics

Soft robots are also proving valuable in exploration missions, particularly in environments that require flexibility and adaptability. This includes applications in space exploration, underwater research, and other unstructured environments.

- Underwater robots: Bio-inspired soft robots can explore marine environments, such as coral reefs, without damaging delicate ecosystems. These robots can navigate through tight spaces or delicate environments, such as shipwrecks or underwater caves, offering insights into ecosystems that traditional rigid robots cannot access.

- Space exploration: Soft robots, with their ability to deform and adapt, are also being considered for use in space missions, where they can assist astronauts in exploration, maintenance, and repair tasks.

Challenges and Future Directions

While the potential for soft robotics is immense, there are still challenges that need to be overcome before they can be widely adopted in industry. These challenges include:

1. Material Limitations

One of the key limitations of soft robotics is the availability of materials that offer both high flexibility and durability. Many of the materials used in soft robots, such as silicones and elastomers, degrade over time, limiting their lifespan and reliability in certain applications.

2. Control Systems

Due to the highly flexible nature of soft robots, their control systems need to be far more sophisticated than traditional robots. Developing control algorithms that can manage soft robots’ movements with precision is an ongoing area of research.

3. Energy Efficiency

Powering soft robots efficiently is another significant challenge. While soft robots tend to be lighter and more adaptable than traditional robots, they often require high amounts of energy to operate their actuators and sensors. Researchers are exploring new energy harvesting methods, such as wireless charging and soft energy sources, to improve the efficiency of these systems.

Conclusion

The field of soft robotics is rapidly evolving, driven by advancements in materials science, engineering, and bio-inspired design. By mimicking the adaptability, dexterity, and flexibility of natural organisms, soft robots offer solutions to challenges that traditional rigid robots cannot address. With applications in healthcare, agriculture, search and rescue, and beyond, soft robotics has the potential to transform industries and improve the quality of life.

While challenges remain in terms of materials, control systems, and energy efficiency, the future of soft robotics looks promising. As the technology continues to mature, we are likely to see a surge in innovative applications that will expand the boundaries of what robots can do. Soft robotics is not just a technological breakthrough; it represents a new paradigm for creating robots that can interact with the world in ways that are more natural, intuitive, and effective.