1. Introduction

Over the past several decades, the manufacturing sector has undergone significant transformations, with automation playing a central role in reshaping production systems. Among the various automation technologies, robots have become an indispensable part of modern factories. Initially designed for simple, repetitive tasks, today’s industrial robots are more intelligent, adaptable, and capable of handling complex tasks such as assembly, welding, painting, inspection, and material handling.

The advent of robotic automation has allowed manufacturers to improve efficiency, increase precision, and reduce production costs, all while enhancing the safety of workers. The continued integration of robots into manufacturing environments has not only improved the economics of production but has also set the stage for the next industrial revolution—Industry 4.0—where cyber-physical systems, smart factories, and the Internet of Things (IoT) come together to create highly efficient, data-driven production systems.

2. The Role of Robots in Manufacturing

Industrial robots are widely used across various stages of the manufacturing process, from assembly lines to packaging and quality control. Their ability to perform repetitive, dangerous, and complex tasks with high precision and speed makes them an essential tool in modern manufacturing environments. Key roles of robots in manufacturing include:

2.1 Assembly

Assembly processes, especially in sectors like automotive manufacturing, benefit greatly from robotic intervention. Robots can perform tasks such as screwing, welding, and part insertion with speed and precision, reducing human error and increasing throughput.

- Automotive Industry: Robots are used for tasks like welding car parts, installing windshields, and assembling vehicle interiors. They handle high-volume, precision-based tasks and ensure consistent quality.

- Electronics Manufacturing: In the electronics industry, robots perform delicate tasks such as circuit board assembly, part placement, and soldering, where human dexterity and precision may not be sufficient.

2.2 Welding

One of the earliest applications of robotics in manufacturing was welding. Robotic welding systems are capable of performing highly accurate and repetitive welding tasks, ensuring uniformity and reducing defects.

- Spot Welding and Arc Welding: Robots are often used for both spot and arc welding in industries such as automotive and shipbuilding, where precision is critical.

- Laser Welding: Newer innovations like robotic laser welding are enabling faster and cleaner welds in industries requiring high-quality joints.

2.3 Material Handling

Material handling robots are used in manufacturing to move raw materials, components, and finished products between stages of the production process. These robots are particularly useful in large-scale operations that require moving heavy or bulky items.

- Pick and Place Robots: Robots that can pick up and place items are widely used for loading and unloading materials, packaging, and sorting.

- AGVs (Automated Guided Vehicles): These robots are commonly used to transport materials within warehouses and factories, reducing human labor and minimizing errors.

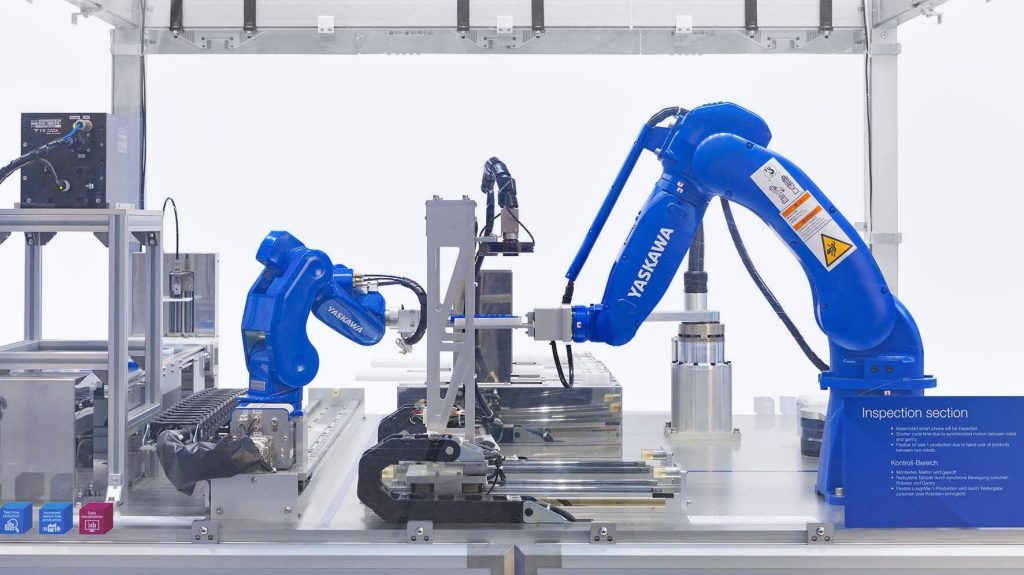

2.4 Quality Control and Inspection

Quality control is an essential part of manufacturing, and robots can play a vital role in inspection tasks. Robots equipped with vision systems can detect defects, measure parts, and verify specifications with greater accuracy than human inspectors.

- Vision Systems: Robots can be integrated with cameras and sensors to detect defects on assembly lines, check for missing components, or verify measurements.

- 3D Scanning: Robots with 3D scanning capabilities are being used for precision measurements, ensuring that parts meet exact tolerances.

3. Key Benefits of Robotics in Manufacturing

The integration of robots into manufacturing offers several significant advantages, including:

3.1 Increased Efficiency and Productivity

Robots are capable of working around the clock, 24/7, without needing breaks or sleep. This continuous operation significantly increases the efficiency and throughput of manufacturing processes. Furthermore, robots can perform tasks at higher speeds and with greater precision than humans, leading to more efficient workflows and reduced production times.

- Cycle Time Reduction: Robots can drastically reduce cycle times, especially in repetitive processes like assembly and material handling, resulting in faster production rates.

- Reduced Downtime: Since robots are less prone to fatigue, they can operate for longer periods without requiring maintenance or downtime, maximizing productivity.

3.2 Precision and Consistency

Robots excel in tasks that require a high degree of precision and consistency. Whether it’s painting a surface, assembling components, or applying a coating, robots are designed to perform these tasks with remarkable accuracy, ensuring uniform quality across production batches.

- Consistent Quality: Robots can repeat tasks with identical precision, ensuring that products meet high-quality standards.

- Reduced Defects: Human workers are prone to fatigue, distraction, and errors, while robots maintain optimal performance at all times, reducing defects and rework.

3.3 Safety and Hazardous Tasks

One of the key reasons robots are introduced into manufacturing environments is to reduce human exposure to dangerous and hazardous tasks. Robots can handle tasks in high-temperature areas, work with toxic substances, or lift heavy objects—activities that would be risky or harmful for human workers.

- Workplace Safety: By handling dangerous tasks, robots help reduce the risk of accidents, injuries, and fatalities in the workplace.

- Hazardous Environments: Robots are ideal for working in environments that are hazardous to human health, such as dealing with chemicals, high radiation, or extreme temperatures.

3.4 Cost Reduction

While the initial investment in robotic systems can be high, the long-term cost savings are substantial. By increasing productivity, reducing errors, and decreasing labor costs, robots provide a significant return on investment over time.

- Labor Cost Savings: Robots can reduce the need for manual labor in repetitive tasks, allowing human workers to focus on more value-added activities.

- Operational Efficiency: Robots optimize production processes, leading to a reduction in material waste, energy consumption, and overall operational costs.

4. Challenges in Integrating Robots into Manufacturing

While the benefits of robotics in manufacturing are undeniable, there are several challenges and obstacles that businesses must address:

4.1 High Initial Investment

The cost of purchasing and installing robotic systems can be a significant barrier for many companies, especially small and medium-sized enterprises (SMEs). However, the long-term benefits in terms of productivity and cost savings often outweigh the initial investment.

- Cost of Robots and Maintenance: While industrial robots can be expensive, advances in technology are helping lower costs, making them more accessible to a wider range of industries.

- Return on Investment (ROI): Businesses must carefully assess the potential ROI to justify the initial costs and ensure that the integration of robots leads to tangible improvements in performance.

4.2 Integration with Existing Systems

Integrating robots into existing manufacturing systems can be complex, particularly for older production lines that were not designed with automation in mind. This often requires substantial redesigns of workflows, equipment, and software.

- System Compatibility: Ensuring that robots can seamlessly interact with existing machines, tools, and software is critical for achieving maximum efficiency.

- Training and Skill Development: Workers must be trained to interact with and manage robotic systems. This can involve both technical training for maintenance and programming, as well as training for new workflows that include robots.

4.3 Workforce Displacement and Labor Issues

The introduction of robots into manufacturing environments can raise concerns about job displacement. While robots are meant to handle repetitive and hazardous tasks, there is a fear that automation may lead to reduced employment opportunities for human workers.

- Reskilling Workers: To address concerns about job losses, companies need to invest in reskilling and upskilling their workforce. This includes training employees to work alongside robots, manage automation systems, and transition to higher-skilled tasks.

- Workforce Transition: A shift toward more advanced manufacturing processes will require workers to adapt to new roles in design, maintenance, and quality control, among others.

5. The Future of Robotics in Manufacturing

The future of robotics in manufacturing looks promising, with ongoing developments in artificial intelligence (AI), machine learning, and collaborative robots (cobots). Some key trends include:

5.1 Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work safely alongside humans in shared workspaces. Unlike traditional industrial robots, which are typically housed in cages or safety zones, cobots can directly interact with human operators.

- Human-Robot Collaboration: Cobots will enable greater collaboration between humans and robots, enhancing flexibility and adaptability in manufacturing environments.

- Smaller and Safer: Cobots are smaller and lighter than traditional robots, making them more adaptable to a variety of tasks and less hazardous in environments with human workers.

5.2 AI and Machine Learning in Robotics

The integration of AI and machine learning will allow robots to become more adaptive, learning from experience and improving their performance over time. This will enable robots to perform a broader range of tasks, including more complex decision-making, fault detection, and predictive maintenance.

- Self-Learning Robots: Future robots could autonomously optimize their operations and improve efficiency, with the ability to adapt to changes in production without human intervention.

- Predictive Maintenance: AI algorithms will enable robots to predict when maintenance is required, minimizing downtime and preventing breakdowns.

5.3 Advanced Sensor Technologies

The advancement of sensor technologies will play a crucial role in enhancing the capabilities of industrial robots. Sensors will provide robots with real-time data about their environment, enabling them to make more informed decisions and interact more effectively with their surroundings.

- 3D Vision Systems: Robots equipped with advanced vision systems will be able to recognize and interact with objects in more dynamic and complex environments.

- Environmental Awareness: Enhanced sensors will allow robots to detect changes in their surroundings, such as the presence of humans or obstacles, improving safety and functionality.

6. Conclusion

Robotic technology has become an integral part of modern manufacturing, transforming industries and driving greater efficiency, precision, and safety. While the adoption of robots in manufacturing presents some challenges, the long-term benefits—reduced costs, enhanced productivity, and improved quality—are undeniable. As robotics continues to evolve, the integration of AI, machine learning, and advanced sensors will enable more adaptable, intelligent, and collaborative robots. The future of manufacturing will undoubtedly be shaped by continued advancements in robotic technology, creating smarter, more efficient production systems that can meet the growing demands of the global market.