Introduction

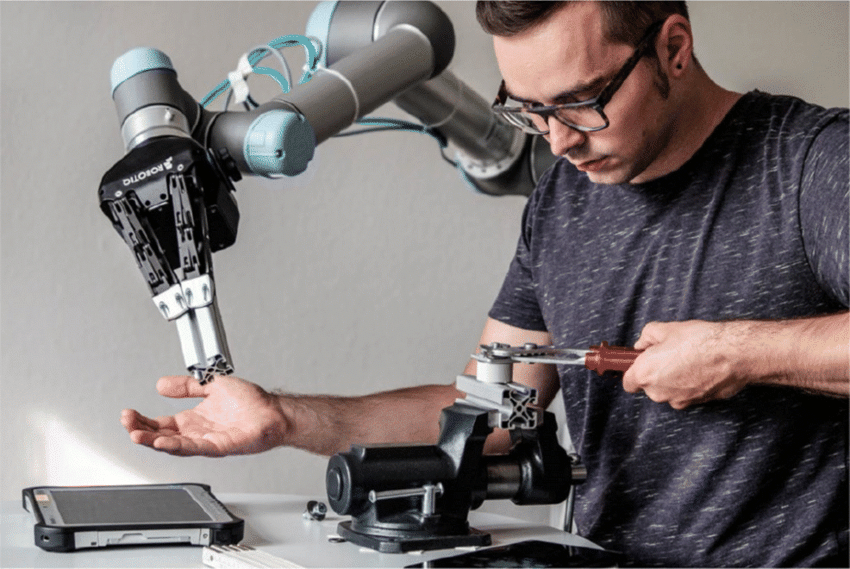

The rise of collaborative robots (cobots) is transforming various industries by enabling machines and humans to work side-by-side in a shared workspace. Unlike traditional industrial robots, which are often confined to isolated areas due to safety concerns, cobots are designed to interact safely and efficiently with human workers. This close interaction requires real-time perception of the environment, particularly the ability to detect, understand, and predict human actions. For cobots to function effectively, they must be capable of constantly sensing and interpreting their surroundings, which includes both the static environment and the dynamic presence of humans.

The ability of a cobot to perceive and respond to human actions is crucial for ensuring safety, efficiency, and productivity in collaborative workspaces. This article will explore the importance of real-time sensing in cobots, the technologies enabling human-robot interaction (HRI), the challenges of real-time perception, and the future of collaborative robots in dynamic work environments.

What are Collaborative Robots?

Collaborative robots, or cobots, are designed to work alongside human operators in a shared workspace. Unlike traditional robots, which are typically confined to cages or safety zones, cobots are built with advanced safety features that allow them to operate in close proximity to humans. These robots are typically lightweight, flexible, and equipped with a range of sensors that enable them to adjust their behavior in response to human actions or changes in their environment.

Cobots can perform a wide variety of tasks, including:

- Assembly: Helping with the assembly of small parts or intricate components.

- Packaging and Sorting: Assisting in packaging, sorting, and moving materials in warehouses and factories.

- Medical Assistance: Assisting surgeons in performing precision surgeries or helping in rehabilitation processes.

- Quality Control: Performing inspections or checks on products in manufacturing settings.

For cobots to work alongside humans effectively, they need to perceive their environment and adapt their actions accordingly. This ability to sense and understand the surroundings is what enables them to be safe, efficient, and productive in real-time operations.

The Importance of Real-Time Perception

Real-time perception in cobots is crucial for two primary reasons:

- Safety: The most important consideration in any collaborative environment is safety. Cobots must have the capability to detect and respond to humans in real-time to avoid collisions, harm, or accidents. Unlike traditional robots that work in isolated environments, cobots share their workspace with human workers, which requires heightened sensitivity to dynamic changes in the surroundings.

- Efficiency: Real-time perception allows cobots to make informed decisions rapidly, which is essential for maintaining productivity. For example, if a human operator is engaged in a task, the robot must be able to detect when the operator has completed the task or when the operator needs help, adjusting its actions accordingly.

To achieve this, cobots need to be equipped with a variety of sensors and technologies that enable them to perceive the environment dynamically.

Technologies Enabling Real-Time Perception in Collaborative Robots

Several sensor technologies enable cobots to perceive their surroundings in real-time, ensuring that they can interact effectively and safely with human workers.

1. Vision Systems (Cameras and Depth Sensors)

Vision systems, including RGB cameras, stereo cameras, and depth cameras (e.g., Intel RealSense, Kinect), are essential for providing cobots with detailed information about the environment. Cameras allow cobots to detect objects, identify human workers, and track movements. Depth sensors enhance this capability by providing 3D perception, allowing robots to understand the relative position of objects and people in space.

- Object Recognition: Vision systems enable cobots to recognize and interact with specific objects in the environment. This is crucial in applications such as assembly, where the robot needs to pick up and manipulate parts with high precision.

- Human Detection: Vision systems can detect human presence and movement, allowing the robot to anticipate human actions and respond appropriately.

2. LiDAR (Light Detection and Ranging)

LiDAR sensors emit laser beams to create detailed 3D maps of the robot’s surroundings. They are particularly useful for creating precise spatial models and detecting obstacles in the environment. LiDAR can be used to map the robot’s workspace and track human movement, ensuring that the cobot can avoid potential collisions with humans or objects.

- Obstacle Detection: LiDAR can detect both stationary and moving obstacles in the robot’s environment, helping the robot navigate safely.

- Spatial Mapping: LiDAR allows cobots to create real-time 3D maps of the workspace, improving their ability to navigate complex environments and collaborate with humans in dynamic settings.

3. Force/Torque Sensors

Force and torque sensors are vital for providing cobots with feedback during interactions. These sensors can detect the force exerted on the robot’s arm or gripper and provide real-time information about the object or human it is interacting with. This allows cobots to handle delicate tasks that require precision, such as assembly or assistance in rehabilitation.

- Human-robot Interaction: Force sensors allow cobots to apply appropriate levels of force when interacting with humans. For example, if a human is guiding the robot, the robot can adjust its force output to match the human’s movement.

- Safety: Force sensors also help detect unexpected collisions or resistance, enabling the cobot to stop or adjust its actions to prevent harm to humans.

4. Proximity Sensors (Ultrasonic, Infrared)

Proximity sensors, such as ultrasonic or infrared sensors, are often used to detect the presence and proximity of humans and objects in the robot’s workspace. These sensors work by emitting sound or light waves and measuring the time it takes for the signal to bounce back after hitting an object.

- Collision Avoidance: Proximity sensors allow cobots to detect the presence of humans in their vicinity and take necessary precautions, such as slowing down or stopping, to avoid accidental collisions.

- Dynamic Adjustments: By continually monitoring the distance between the robot and nearby objects or humans, proximity sensors help cobots adjust their movements in real-time.

5. Human-Machine Interface (HMI) Systems

In some collaborative environments, cobots rely on Human-Machine Interface (HMI) systems, which enable more intuitive interaction between humans and robots. HMIs can include touchscreens, voice recognition, and gesture-based control systems, which allow human workers to provide commands or feedback to the robot without physical contact.

- Gesture Recognition: Some cobots are equipped with sensors that can recognize specific hand gestures or body movements, allowing humans to control the robot’s actions with simple gestures.

- Voice Command: In some scenarios, voice recognition systems allow humans to issue commands to the robot, enhancing ease of use in dynamic work environments.

Real-Time Perception for Human-Robot Interaction (HRI)

Human-Robot Interaction (HRI) is a critical aspect of cobot functionality. Unlike traditional robots that are often programmed to follow fixed tasks in isolation, cobots must be able to adapt to human actions, interpret their intentions, and respond appropriately. The success of HRI in collaborative robotics depends heavily on the robot’s real-time perception capabilities.

1. Predicting Human Behavior

For a cobot to effectively collaborate with a human worker, it must not only detect the human’s presence but also predict their movements and intentions. Predicting human behavior is a complex task that requires advanced algorithms and machine learning models.

- Movement Prediction: Cobots need to anticipate the movements of human workers to avoid collisions and work in harmony with them. For example, if a human is moving toward a particular object, the cobot must predict their path and adjust its own actions accordingly.

- Intent Recognition: Cobots can use sensor data to recognize when a human is requesting help or offering assistance. Machine learning algorithms are increasingly being used to interpret human gestures or changes in posture, enabling the robot to respond to these cues in real-time.

2. Ensuring Safety and Comfort

Real-time perception is also essential for ensuring that cobots operate safely and comfortably alongside humans. Cobots need to be able to sense when a human worker is too close, and adjust their behavior accordingly to avoid accidents. In some cases, this may mean slowing down, stopping, or changing direction entirely.

- Speed Control: Many cobots are equipped with sensors that allow them to slow down or stop when a human enters their proximity. For example, an industrial cobot may slow down its movements when working near human workers to avoid potential accidents.

- Comfortable Interaction: Cobots must also be designed to interact with humans in a way that feels natural and comfortable. This includes adapting their movements to the pace of human workers and ensuring that their actions are predictable and non-threatening.

Challenges in Real-Time Perception for Collaborative Robots

Despite the advances in sensing and perception technologies, there are still several challenges that need to be addressed to improve the real-time perception capabilities of cobots.

- Sensor Accuracy and Reliability: Sensors must provide accurate and reliable data in real-time, especially in dynamic and cluttered environments. Inaccurate sensor readings can lead to collisions, malfunctions, or inefficiencies.

- Complex Environments: Collaborative robots often operate in environments that are constantly changing, with varying lighting conditions, moving objects, and multiple human workers. Ensuring that the robot can adapt to these changes in real-time is a significant challenge.

- Processing Power: Real-time perception and decision-making require significant computational resources. The robot must be able to process data from multiple sensors quickly and efficiently to make informed decisions in real-time.

- Human Variability: Humans are unpredictable and can vary significantly in their behavior, which makes it difficult for robots to consistently predict their actions. Training robots to understand a wide variety of human behaviors and actions is a complex task.

The Future of Collaborative Robots

As technology advances, we can expect continued improvements in the real-time perception capabilities of cobots. Advances in machine learning, AI, and sensor fusion will enable cobots to better understand and interact with their environments and human collaborators. The future of collaborative robots lies in their ability to seamlessly integrate into dynamic work environments, safely and efficiently working side-by-side with humans.

In conclusion, real-time perception is the cornerstone of successful human-robot collaboration. By integrating advanced sensors and intelligent algorithms, cobots are becoming more capable of sensing, understanding, and interacting with their surroundings, particularly in dynamic and human-centric environments. As the technology continues to evolve, we can expect collaborative robots to play an increasingly integral role in a variety of industries, from manufacturing to healthcare, where they will enhance productivity, safety, and human-robot collaboration.