The advent of robotics, artificial intelligence (AI), and big data analytics has triggered a profound transformation across numerous industries. One of the most significant areas benefiting from these technologies is manufacturing. Traditionally, manufacturing processes were linear, standardized, and based on mass production principles. However, as market demands evolve towards personalization, customization, and complex product configurations, manufacturers need to adapt. Integrating robotic technology with big data analytics and AI enables companies to produce with greater precision, flexibility, and speed, thereby unlocking the ability to meet personalized market demands efficiently.

This article explores how the synergy between robotics, big data analytics, and AI is revolutionizing modern manufacturing practices. We will discuss the key technologies involved, the advantages of this integration, real-world applications, challenges, and the future trajectory of these innovations. By the end, we will see how this fusion not only improves operational efficiency but also provides a strategic advantage in meeting diverse and dynamic consumer demands.

Introduction: The Need for Precision and Personalization in Modern Manufacturing

In the age of Industry 4.0, the demand for personalized products is growing rapidly. Consumers are seeking unique, high-quality products tailored to their individual preferences. This trend, driven by digitalization and globalization, requires manufacturing systems to be more flexible, data-driven, and agile than ever before.

Traditionally, mass production has focused on creating uniform products in large quantities, with limited customization options. However, this approach does not align well with current market trends, where customers increasingly demand products tailored to their specific needs. As a result, manufacturers must evolve their production strategies to meet this demand for personalized and precision-engineered products, all while maintaining cost-effectiveness, speed, and efficiency.

This is where the integration of robotics, big data, and AI plays a pivotal role. By combining these advanced technologies, manufacturers can now produce highly customized products without sacrificing efficiency or scalability.

1. Robotics: The Backbone of Smart Manufacturing

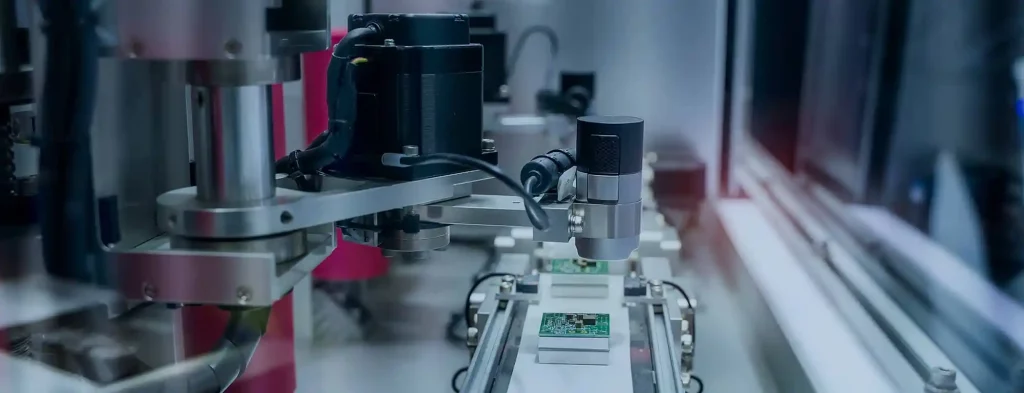

Robotics has been a key driver of automation in manufacturing for decades. Industrial robots have significantly increased productivity, reduced human error, and improved safety on factory floors. However, with the rapid evolution of AI, robots are becoming far more advanced, capable of executing complex tasks and collaborating with humans in co-bot environments.

Key Benefits of Robotics in Manufacturing:

- Automation of Repetitive Tasks: Robots can take over repetitive and physically demanding tasks such as assembly, packaging, and material handling. This reduces the burden on human workers and allows them to focus on higher-value tasks.

- Precision and Quality Control: Robots offer unparalleled precision, reducing defects and ensuring consistent product quality.

- Flexibility and Adaptability: Advanced robots can be reprogrammed quickly to accommodate different tasks or product variations, allowing manufacturers to respond more swiftly to changes in demand.

- Collaboration with Humans: Unlike traditional robots that operate in isolation, collaborative robots (cobots) can work alongside human operators safely and efficiently, making it easier for manufacturers to integrate automation without major changes to existing workflows.

In combination with AI and big data, robots can become highly adaptable systems capable of producing customized products in a wide variety of configurations.

2. The Role of Big Data Analytics in Manufacturing

The term big data refers to the vast amounts of structured and unstructured data generated across industries. In manufacturing, big data arises from various sources such as machine sensors, production equipment, customer feedback, and market trends. The ability to collect and analyze this data is transforming how manufacturers understand and respond to market demands.

Big Data in Manufacturing: Key Applications:

- Predictive Maintenance: By collecting real-time data from sensors on manufacturing equipment, businesses can predict when machines will require maintenance before they break down. This reduces downtime, improves asset longevity, and lowers maintenance costs.

- Process Optimization: Data-driven insights can be used to optimize production processes by identifying inefficiencies, bottlenecks, and areas for improvement. Manufacturers can continually refine their processes to increase efficiency and quality.

- Demand Forecasting: Big data analytics enables manufacturers to analyze market trends and consumer behaviors to predict future demand more accurately. By leveraging data on consumer preferences, manufacturers can produce just the right amount of customized products to meet specific needs, minimizing waste.

- Supply Chain Optimization: Big data also enhances the supply chain, allowing businesses to track the movement of raw materials and finished products in real-time, optimize inventory levels, and reduce lead times.

Through the application of big data analytics, manufacturers can achieve data-driven decision-making that results in better overall efficiency, cost reduction, and market responsiveness.

3. Artificial Intelligence: Bringing Intelligence to Robotics and Manufacturing

AI is the cornerstone of modern technological advancements in manufacturing. By enabling machines to learn, reason, and make decisions based on data, AI empowers robotics and other automated systems to be more intelligent and flexible.

Key Contributions of AI in Manufacturing:

- Machine Learning for Quality Control: AI algorithms can analyze vast amounts of production data to detect patterns and anomalies, making them ideal for quality inspection. By utilizing image recognition and predictive algorithms, AI can identify defects during the production process, ensuring higher product quality.

- Intelligent Robotics: AI enhances the capabilities of robots, enabling them to autonomously perform complex tasks such as assembly, packaging, and even testing. Robots can adapt to changes in the production line based on real-time inputs and learn from past experiences to improve efficiency over time.

- Customization through AI-Driven Design: AI can also support personalized manufacturing by helping companies design products that meet specific customer preferences. Using generative design and optimization algorithms, AI can assist in creating customized parts or products that maximize both performance and manufacturability.

- Real-Time Decision-Making: AI-driven systems are capable of processing data in real-time and making decisions autonomously. This allows manufacturers to respond to sudden shifts in demand, environmental factors, or machine conditions without human intervention, leading to greater efficiency and faster production cycles.

AI makes it possible for manufacturing systems to be much more agile, helping companies switch between product types and respond to market fluctuations quickly and effectively.

4. Synergy: How Robotics, Big Data, and AI Work Together

When integrated, robotics, big data, and AI create a powerful ecosystem that significantly enhances the efficiency and flexibility of manufacturing systems. The synergy of these technologies enables smart manufacturing, where machines, robots, and humans collaborate seamlessly, and data drives every aspect of the production process.

Key Benefits of Integration:

- Dynamic Customization: By combining AI with robotics, manufacturers can easily create customized products on-demand. AI can analyze consumer data and translate those insights into specific production instructions, while robots perform the necessary tasks with high precision and speed.

- Enhanced Flexibility: The combination of robotics and big data allows for adaptive manufacturing. For example, if market demand shifts or a design change is requested, robotic systems can quickly reconfigure themselves to accommodate new requirements without requiring substantial downtime or reengineering.

- Improved Efficiency: Through continuous learning and data feedback loops, AI-enhanced robots can optimize their movements, tasks, and workflows, reducing energy consumption and improving output. AI also enables predictive analytics, helping businesses avoid disruptions and maintain consistent production levels.

- Cost Savings: The automation enabled by robotics, the insight provided by big data, and the decision-making power of AI collectively help businesses reduce operational costs, minimize waste, and optimize resource allocation.

5. Real-World Applications of Robotics, Big Data, and AI in Manufacturing

The integration of these technologies has already been applied in several industries, showcasing their potential to revolutionize manufacturing. Below are some notable examples:

- Automotive Industry: Companies like BMW and Tesla use robotics and AI to create customized vehicles. AI analyzes customer preferences and production data, while robots assemble parts with high precision. This combination enables manufacturers to meet the demand for highly personalized vehicles without slowing down production.

- Electronics Manufacturing: Companies like Foxconn have integrated robots with AI and big data to produce electronics at scale. Robots handle tasks such as component placement, while AI ensures quality control, and big data optimizes the supply chain.

- Textiles and Fashion: Fashion retailers such as Nike and Adidas have adopted smart manufacturing techniques that use AI for product design and robots for assembly, allowing for rapid prototyping and on-demand production. Big data helps these companies understand trends and predict consumer demand, ensuring they only produce what is needed.

- Food and Beverage Industry: Robots equipped with AI and data analytics are being used in the food production sector to handle repetitive tasks such as packaging, sorting, and quality inspection. Data-driven insights enable food producers to tailor products to consumer preferences while optimizing ingredient sourcing and production cycles.

6. Challenges and Future Outlook

Despite the immense potential, the integration of robotics, big data, and AI into manufacturing is not without its challenges. These include:

- High Initial Investment: While the long-term benefits are clear, the upfront costs associated with implementing these technologies can be a barrier, particularly for SMEs.

- Data Security and Privacy: With the increased reliance on big data, businesses must address concerns related to data security and privacy, ensuring that sensitive consumer data is protected.

- Workforce Transition: As robots and AI systems take over certain tasks, human workers will need to acquire new skills to operate, maintain, and collaborate with these advanced technologies.

However, with the continuous advancement of AI, robotics, and big data analytics, the future of smart manufacturing looks promising. As technology becomes more affordable and accessible, the adoption of these integrated systems will only increase.

Conclusion

The integration of robotics, big data analytics, and AI has reshaped the landscape of modern manufacturing. Together, these technologies provide the foundation for a data-driven, agile, and highly customizable production environment capable of meeting the growing demand for personalized products. As manufacturers continue to innovate and refine these systems, the potential for more efficient, flexible, and sustainable production practices is immense.

The future of manufacturing lies in leveraging these cutting-edge technologies to adapt to evolving market needs, optimize production workflows, and maintain competitive advantage in an increasingly dynamic and globalized world.