Introduction

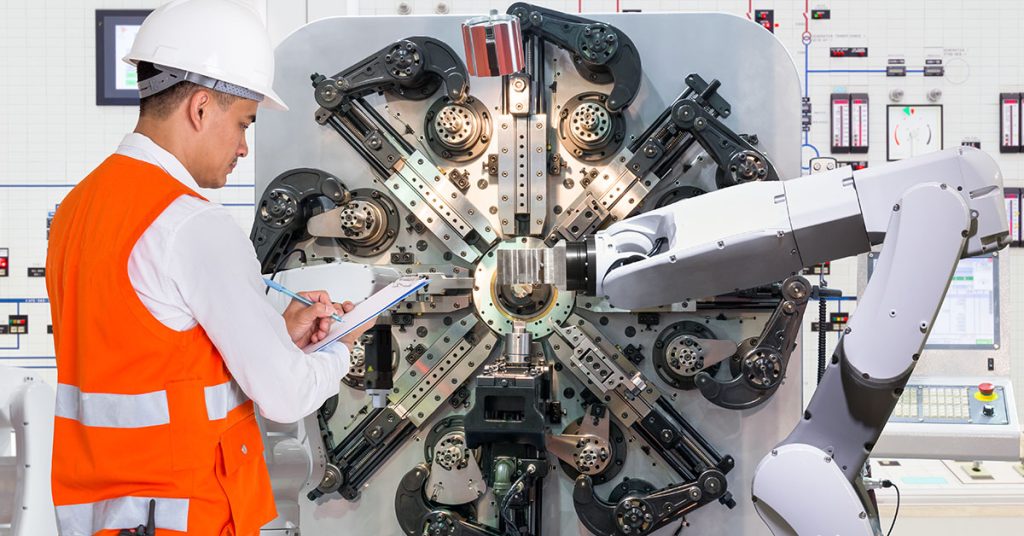

The rapid evolution of robotics, powered by advanced artificial intelligence (AI), machine learning, and sophisticated sensors, has led to a dramatic transformation in modern manufacturing. A new class of robots, known as collaborative robots (cobots), is enabling a paradigm shift in how we approach industrial production. Unlike traditional industrial robots, which are typically isolated in cages or fenced-off areas for safety, cobots are designed to work side-by-side with human workers, enhancing flexibility, efficiency, and safety in the production environment.

The rise of Industry 4.0 has brought about a more connected and digitalized manufacturing ecosystem, and cobots are at the forefront of this change. By blending the capabilities of robots with human dexterity and decision-making, cobots are revolutionizing the way factories operate. This human-robot collaboration promises to create more flexible, customizable, and safer production models that go beyond the rigid and repetitive processes of traditional manufacturing systems.

In this article, we will explore how collaborative robots are transforming manufacturing, the ways they enhance workplace flexibility and safety, and how they are changing the fundamental dynamics of industrial production.

1. Understanding Collaborative Robots (Cobots)

a. What Are Collaborative Robots?

Collaborative robots, or cobots, are robots designed specifically to work in tandem with human workers in a shared workspace. Unlike traditional industrial robots, which typically operate autonomously or in isolation from humans, cobots are equipped with safety features that allow them to safely operate near humans. These features may include force sensors, collision detection, and vision systems, all of which help the robot adapt its behavior based on human actions.

Cobots are typically smaller, lighter, and more flexible than traditional industrial robots, making them more adaptable to a variety of tasks. They are often used for repetitive, tedious, or dangerous tasks, allowing human workers to focus on more complex, creative, or decision-making activities. The goal is not to replace humans but to complement their abilities, creating a more efficient, effective, and ergonomic work environment.

b. Key Features of Cobots

Some of the defining features of cobots include:

- Ease of programming: Cobots are often designed to be user-friendly, with intuitive interfaces that allow workers to quickly teach them new tasks, even without extensive technical knowledge.

- Safety: Cobots come with built-in safety mechanisms, such as soft-touch materials and collaborative sensors that help them detect human presence and avoid collisions.

- Flexibility: Cobots are designed to perform a wide range of tasks in various environments, making them highly adaptable to different production scenarios.

- Size and mobility: Cobots are generally smaller and more lightweight than traditional robots, making them easier to integrate into existing production lines or workspaces.

These features combine to make cobots highly versatile, easy to deploy, and scalable for different manufacturing needs.

2. Enhancing Flexibility in Production

a. Customization of Workflows

One of the biggest advantages of cobots is their ability to adapt to the changing needs of a production environment. In traditional manufacturing systems, production lines are often fixed, with machines designed to perform one specific task for a long period. This lack of flexibility can make it difficult to accommodate changes in production volume, product variety, or customer demands.

Cobots, on the other hand, are inherently flexible and can be reprogrammed or re-tasked quickly to accommodate different products or processes. This level of flexibility allows manufacturers to:

- Produce a wider variety of products on the same production line.

- Quickly reconfigure production to respond to changing market demands or customer preferences.

- Reduce setup times and costs by eliminating the need for extensive downtime or retooling between production runs.

By enabling the easy reconfiguration of workflows and production lines, cobots allow manufacturers to move toward customized production, where individual components can be made quickly and efficiently in response to consumer demand.

b. Shortening Production Cycles

Traditional industrial robots are often designed for high-volume, long-cycle tasks, such as assembly or welding. While effective for mass production, these robots are less suited to small-batch or custom production runs. Cobots, however, can easily shift between different tasks and production cycles, making them ideal for shorter production runs with higher customization.

For instance, in the automotive industry, cobots can help assemble vehicles with different specifications, easily adjusting to different parts and configurations without the need for complex retooling. In electronics manufacturing, cobots can handle delicate tasks such as soldering, testing, and packaging, offering precision and flexibility for smaller, specialized batches.

This shift toward agile manufacturing allows companies to respond faster to market trends and customer needs, all while maintaining high efficiency and cost-effectiveness.

3. Improving Workplace Safety and Ergonomics

a. Reducing Risk of Injury

In traditional manufacturing settings, industrial robots are often isolated in safety cages or barriers to protect workers from injury. However, the rigid separation between humans and robots also limits collaboration and creates inefficiencies, particularly in environments that require human dexterity, decision-making, or quality control.

Cobots, by contrast, are designed to work directly alongside human workers in a shared workspace. Through force and torque sensors, cobots can detect when they come into contact with a human, immediately slowing down or stopping to avoid injury. This level of sensitivity allows robots to perform tasks that would otherwise be too dangerous for humans, such as lifting heavy objects or working with hazardous materials, while keeping human workers out of harm’s way.

Moreover, cobots can reduce repetitive strain injuries by taking on physically demanding tasks that would otherwise put stress on a human worker’s body. In manufacturing environments, this means cobots can handle tasks such as heavy lifting, carrying materials, or performing repetitive motions—allowing workers to focus on tasks that require more creativity, decision-making, or fine motor skills.

b. Enhancing Ergonomics

In addition to improving physical safety, cobots can enhance workplace ergonomics by reducing the amount of physical strain placed on workers. For example:

- Assembly tasks: Cobots can work together with human operators to handle heavy components, reducing the need for workers to lift or manipulate bulky materials.

- Packaging tasks: Cobots can automate packaging processes, lifting items, packing them, and labeling them, all while maintaining an ergonomic workflow for the human worker.

- Precision tasks: Cobots can take on tasks that require high precision, such as screw driving, soldering, or testing, ensuring that workers can focus on critical thinking and quality assurance.

By taking on the physically demanding or repetitive tasks, cobots allow workers to focus on more intellectually challenging and rewarding aspects of their jobs, improving overall job satisfaction and reducing the likelihood of workplace injuries.

4. Cobots in Action: Real-World Examples

a. Automotive Manufacturing

In the automotive industry, cobots have been integrated into assembly lines to improve efficiency, precision, and safety. Cobots work alongside human workers to perform tasks such as assembly, welding, painting, and inspection. For instance, cobots can assist in lifting and positioning heavy components, enabling humans to focus on more intricate assembly tasks or quality control.

One example is Ford’s use of cobots in its production facilities. Cobots are deployed to assist workers in lifting heavy parts, such as bumpers and doors, improving worker safety while increasing productivity. By sharing the workload, cobots help human workers complete tasks more efficiently, reducing fatigue and minimizing the risk of injury.

b. Electronics and Consumer Goods Manufacturing

Cobots are also being widely adopted in electronics manufacturing, where the demand for high precision and small-batch production is growing. In this sector, cobots assist with tasks such as soldering, testing, assembly, and packaging.

At Universal Robots, cobots are used in PCB assembly, handling delicate components and performing quality control checks. The flexibility of these robots allows for rapid reprogramming to accommodate different product models or configurations, offering a competitive edge in industries that require high levels of customization.

c. Food and Beverage Industry

In the food industry, cobots are utilized for tasks such as packaging, sorting, and quality control. They ensure products are prepared quickly and safely, while reducing human exposure to hazardous environments or conditions such as extreme temperatures.

5. The Future of Collaborative Robotics

As technology continues to evolve, the future of collaborative robotics is poised to become even more transformative. With the integration of artificial intelligence (AI), machine learning, and internet of things (IoT) technologies, cobots will become more autonomous, intelligent, and integrated into smart manufacturing environments.

By combining AI with advanced sensors and vision systems, future cobots will be able to understand complex human gestures, anticipate needs, and make decisions in real time. This will allow for even more seamless collaboration between humans and robots, enhancing productivity, safety, and efficiency in ways that were previously unimaginable.

Conclusion

Collaborative robots are redefining the landscape of manufacturing by providing a flexible, safe, and efficient solution for modern production needs. These robots enable human workers to focus on higher-level decision-making and creative tasks, while simultaneously improving safety, reducing physical strain, and enhancing overall workplace ergonomics.

The future of manufacturing will undoubtedly be shaped by the continued integration of cobots, as they allow industries to become more agile, responsive, and sustainable. By transforming traditional production workflows, cobots are helping businesses embrace the opportunities presented by Industry 4.0, ushering in a new era of human-robot collaboration that maximizes both human potential and technological advancement.