Introduction

The landscape of the modern workplace is undergoing a significant transformation due to the integration of robotics and automation technologies. As robots become more capable of performing complex tasks, they are increasingly working alongside humans in various industries, ranging from manufacturing and healthcare to retail and logistics. These collaborative relationships—often referred to as human-robot collaboration or cobotics—are changing the way we think about work, productivity, and the role of humans in the workplace.

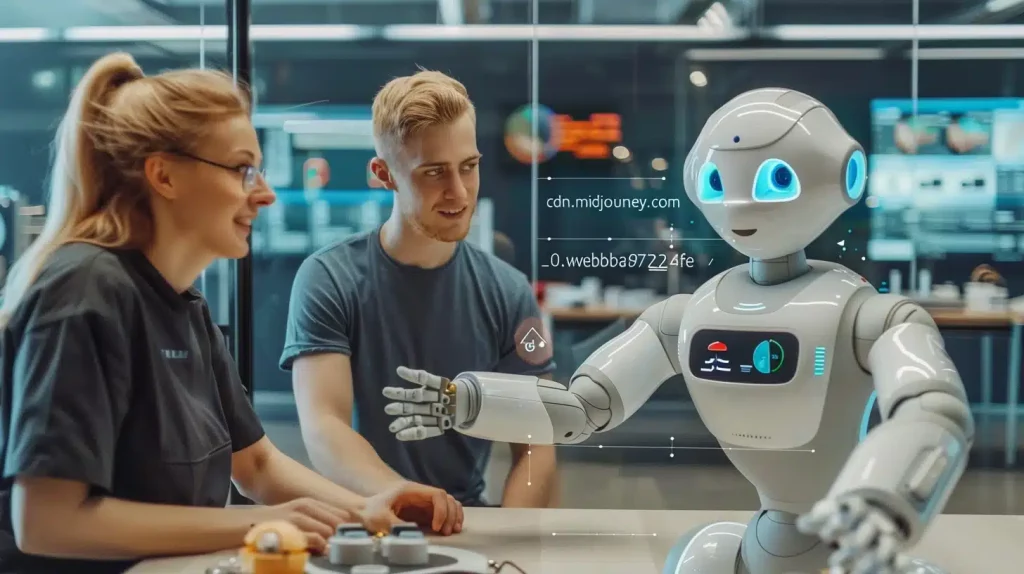

Gone are the days when robots were isolated in factories or restricted to performing repetitive tasks behind the scenes. Today, robots and humans are co-located, working in close proximity, and sometimes even interacting directly to achieve shared goals. This shift presents both opportunities and challenges, particularly regarding how humans and robots can coexist, complement one another, and maximize their collective potential.

This article explores the various models of human-robot collaboration in the workplace, the technological advancements driving these interactions, and the social, ethical, and practical implications of working alongside robots.

1. The Rise of Human-Robot Collaboration: An Overview

The concept of robots working alongside humans has evolved considerably in recent years. In the past, robots were designed primarily for automation in controlled environments, often performing highly repetitive tasks in industrial settings. They were typically separated from human workers for safety reasons, operating behind barriers or in restricted zones. However, recent developments in robotics and artificial intelligence (AI) have led to the emergence of collaborative robots, or cobots.

Cobots are robots that are specifically designed to work alongside humans in a shared workspace. Unlike traditional industrial robots, which require safety fences or cages to prevent accidents, cobots are equipped with advanced sensors, AI algorithms, and safety mechanisms that enable them to safely interact with human workers. This has opened the door to a wide range of new applications where robots and humans can collaborate in a fluid, dynamic, and mutually beneficial manner.

The growing sophistication of robots is also supported by advances in AI, machine learning, and robotics engineering, which have enabled robots to perform tasks that were once thought to be exclusive to humans. Whether it’s assembling products on a factory floor, assisting with surgeries in hospitals, or delivering goods in warehouses, robots are becoming indispensable partners in a variety of work environments.

2. Models of Human-Robot Collaboration

There are several different models of human-robot collaboration, each suited to different tasks, industries, and levels of human interaction. Understanding these models is crucial to realizing the full potential of human-robot cooperation.

- Cooperative Collaboration (Task Sharing): In this model, robots and humans work together to accomplish a shared task, with each contributing complementary strengths. For example, in an assembly line, a robot might handle heavy lifting and precise positioning, while the human worker performs tasks requiring dexterity, problem-solving, or creative thinking. This approach maximizes the strengths of both the robot and the human worker, leading to improved efficiency and productivity.

- Sequential Collaboration (Task Division): In sequential collaboration, robots and humans perform parts of a task in a predetermined order. This model is commonly seen in manufacturing processes, where robots may handle certain phases of production (e.g., welding, painting) while humans perform the final assembly or quality checks. The coordination between robot and human is key to the success of this model, as it ensures a smooth workflow and minimal disruption.

- Assistive Collaboration: In some work environments, robots are used to assist human workers by providing tools or information, rather than directly participating in the task. For example, in healthcare settings, robots may assist surgeons by providing real-time data or offering tools during surgeries, while the human remains in control of the procedure. Similarly, in logistics, robots can deliver parts or supplies to human workers on the shop floor, reducing downtime and improving efficiency.

- Autonomous Assistance: In this model, robots work autonomously but are designed to provide assistance to human workers as needed. For example, autonomous robots in warehouses or factories might move materials or products to designated locations, enabling human workers to focus on higher-level tasks. While the robot operates autonomously, its actions are coordinated with human workflows to ensure seamless operation.

Each model of collaboration has its own advantages, depending on the specific task, the level of interaction between the human and robot, and the nature of the work being performed. The key to successful collaboration is understanding the complementary roles that humans and robots can play, and designing systems that allow them to work together in harmony.

3. Technological Advancements Enabling Human-Robot Collaboration

The success of human-robot collaboration hinges on the continuous development of advanced technologies. Several key innovations are driving the progress of cobots, making them more capable and adaptable to a variety of workplace environments:

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning enable robots to learn from their environment, adapt to new situations, and improve over time. By processing data from sensors and cameras, robots can gain a deeper understanding of their surroundings, recognize objects, and make decisions autonomously or in collaboration with humans. For example, AI-powered robots can be trained to identify defects in products during quality control processes, or they can learn to adapt their movements based on the actions of human workers.

- Advanced Sensors and Vision Systems: Sensors such as cameras, lidar, and proximity sensors play a crucial role in enabling robots to interact safely with humans. These sensors allow robots to detect and respond to human movements, ensuring that they can work in close proximity without posing a safety risk. In addition, advanced vision systems enable robots to recognize objects and manipulate them with precision, which is critical in many collaborative settings.

- Human-Robot Interaction (HRI) Interfaces: To facilitate collaboration, robots must be able to communicate effectively with human workers. HRI interfaces, such as touchscreens, voice commands, and even gesture recognition systems, allow humans to control and communicate with robots intuitively. By simplifying interactions, these interfaces help bridge the gap between human and robotic capabilities, making collaboration more seamless.

- Safety Mechanisms and Compliance: Safety is a top priority in human-robot collaboration, and significant progress has been made in developing safety systems that allow robots to work safely in close proximity to humans. These systems include collision detection, force sensors, and emergency stop functions, which enable robots to halt operations if they sense a potential danger. Regulatory bodies, such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI), have developed guidelines and safety standards to ensure that robots operate in compliance with workplace safety regulations.

4. Benefits of Human-Robot Collaboration

Human-robot collaboration offers a wide range of benefits that can enhance productivity, efficiency, and safety in the workplace. Some of the key advantages include:

- Increased Productivity: By leveraging the strengths of both humans and robots, workplaces can achieve higher levels of productivity. Robots can handle repetitive, physically demanding, or dangerous tasks, while humans can focus on tasks that require creativity, problem-solving, and decision-making. This balance leads to more efficient workflows and faster output.

- Improved Safety: Robots can perform dangerous tasks, such as handling hazardous materials or working in high-risk environments, reducing the potential for human injury. For example, in construction, robots can be used to lift heavy objects or operate in hazardous areas, ensuring that human workers are not exposed to dangerous conditions.

- Enhanced Quality Control: Robots can perform tasks with a high degree of precision, improving the quality and consistency of products. In manufacturing, robots can be used for quality control tasks such as inspection, testing, and assembly, ensuring that products meet rigorous standards. This is particularly valuable in industries like electronics, automotive, and pharmaceuticals, where precision is crucial.

- Job Creation and Skill Development: While there are concerns that automation may lead to job displacement, human-robot collaboration can actually create new job opportunities. As robots take on more routine tasks, human workers can shift focus to more value-added roles that require higher levels of skill, such as robot programming, maintenance, and process optimization. Furthermore, robots provide opportunities for workers to learn new skills and work alongside cutting-edge technologies.

5. Challenges of Human-Robot Collaboration

Despite the many advantages, there are several challenges that need to be addressed to fully realize the potential of human-robot collaboration. These challenges include:

- Workplace Integration: Integrating robots into existing workflows and environments can be complex. Robots must be designed to work seamlessly with human workers, and this often requires significant changes to work processes, infrastructure, and training programs. Additionally, ensuring that robots can adapt to different tasks and work with diverse teams of humans is a critical challenge.

- Human-Robot Interaction: While technology has made great strides in enabling human-robot interaction, there are still hurdles to overcome in making these interactions intuitive and natural. Ensuring that robots understand human intentions, respond to gestures and commands, and effectively collaborate with workers remains a significant research area in robotics.

- Ethical and Social Considerations: The widespread use of robots in the workplace raises ethical questions about job displacement, data privacy, and the role of humans in the labor market. Addressing these concerns requires careful thought and planning to ensure that robots are integrated into the workplace in a way that benefits both workers and organizations.

6. The Future of Human-Robot Collaboration

The future of human-robot collaboration looks promising, with continued advancements in technology and the growing adoption of robots in various sectors. In the coming years, robots will become even more capable, adaptable, and integrated into the workplace. As AI, machine learning, and robotics continue to evolve, the boundaries between human and robotic roles will continue to blur, leading to more dynamic and flexible work environments.

However, to ensure the successful integration of robots into the workplace, it is essential to address the challenges of safety, ethics, and social impact. By fostering collaboration between technologists, policymakers, and industry leaders, we can create a future where robots and humans work together to unlock new possibilities for productivity, innovation, and human well-being.

Conclusion

Human-robot collaboration is transforming the way we work, creating opportunities for enhanced productivity, safety, and quality control in a variety of industries. While challenges remain in terms of integration, interaction, and ethical considerations, the potential benefits far outweigh the risks. As technology continues to evolve, human-robot collaboration will become an increasingly vital component of the workplace, reshaping how we approach tasks and redefine the future of work. The key to success lies in developing the right balance of innovation, safety, and human-centered design, ensuring that robots can serve as valuable partners without replacing the essential role of human workers.