1. Introduction

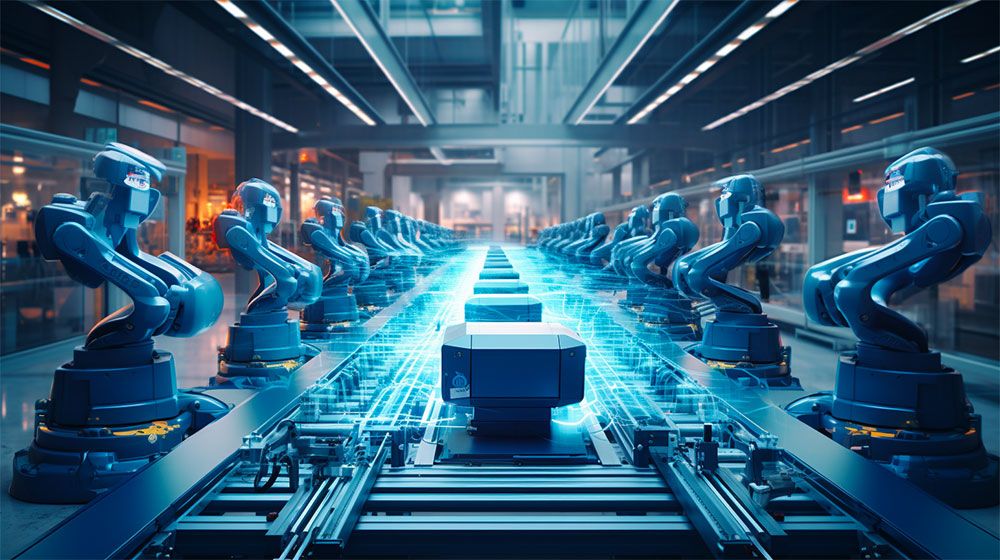

Over the past few decades, industrial robots have evolved from simple tools used to automate repetitive tasks to advanced systems integrated into every aspect of business strategy. The increasing capabilities of robots, powered by artificial intelligence (AI), machine learning, and advanced sensors, have redefined what is possible in manufacturing, logistics, healthcare, and other sectors.

Today, robots are no longer seen merely as workers on a factory floor; they have become vital to strategic decision-making, influencing everything from product design and manufacturing processes to market expansion and customer service. As businesses continue to embrace automation, robots are playing a key role in reshaping industries and business models.

This article explores the evolving role of robots in business strategy and how companies are leveraging robotic technologies to not only improve operational efficiency but also enhance their competitive edge in an increasingly dynamic and complex business environment.

2. The Evolution of Robotics in Business

2.1 From Tools to Strategic Assets

Historically, robots were introduced into industries to improve the efficiency of production lines. Early robots, such as those in the automotive industry, were used primarily for simple tasks like welding, painting, and assembly. These robots were viewed as tools to increase productivity, reduce labor costs, and improve product consistency.

However, over time, advancements in artificial intelligence (AI) and machine learning have significantly enhanced the capabilities of robots. Today, robots can handle complex tasks, such as:

- Real-time data analysis and decision-making.

- Collaboration with human workers in shared spaces.

- Customization of production lines for highly flexible manufacturing.

With such capabilities, robots are now seen as integral to business strategy rather than just tools for production. They enable businesses to be more agile, reduce lead times, enhance product quality, and quickly adapt to changing market conditions.

2.2 Robots in Non-Manufacturing Sectors

Robotic technology has also permeated industries beyond manufacturing. For instance, in logistics, robots are being used for tasks like inventory management, automated delivery, and warehouse operations. In healthcare, surgical robots assist in performing complex medical procedures with greater precision, and robots are increasingly being used for elderly care and rehabilitation. Additionally, robots are playing a crucial role in retail and customer service by offering personalized experiences and supporting operations in e-commerce and store management.

3. How Robots Enhance Business Strategy

3.1 Driving Operational Efficiency

The most apparent benefit of robotic technology in business is its ability to drive operational efficiency. Robots can work continuously, 24/7, without the need for rest, which dramatically increases output. Their precision and reliability help ensure consistent quality across products, thereby reducing waste and improving profitability.

Key ways robots enhance operational efficiency include:

- Minimizing Downtime: Robots can perform tasks without the risk of fatigue, resulting in fewer production stoppages and higher uptime.

- Speed and Precision: Robotic systems can execute tasks with extreme accuracy, reducing the chances of human error and ensuring high-quality output.

- Optimized Workflows: Robots can improve workflows by handling repetitive, labor-intensive tasks, allowing human workers to focus on higher-value activities.

3.2 Innovation and Product Development

In industries like automotive design, consumer electronics, and fashion, robots are driving innovation by enabling businesses to rapidly prototype and test new designs. Advanced robots equipped with AI and 3D printing capabilities can produce prototypes at a fraction of the cost and time compared to traditional methods.

- Flexible Production Lines: Robots enable mass customization, where products are designed to meet specific customer needs without sacrificing the efficiency of mass production. For example, in the automotive industry, robots can adapt assembly lines to produce different vehicle models with minimal downtime.

- Rapid Prototyping: In industries such as electronics, robots can be used for quick iterative designs, allowing companies to respond to market demands more swiftly.

3.3 Enhancing Flexibility and Scalability

Robots play a crucial role in enhancing business flexibility. In today’s fast-paced markets, businesses must be agile enough to respond to shifting consumer preferences, disruptions in the supply chain, and unforeseen circumstances like pandemics or natural disasters.

- Agile Manufacturing: Robots allow businesses to quickly switch between different production tasks, enabling flexible manufacturing. For instance, a factory can use the same robotic system for assembling multiple types of products without needing a complete redesign.

- Scalability: As businesses expand or enter new markets, robots allow for easy scaling of operations. Adding robots to a production line can quickly increase capacity without requiring significant investment in human labor or training.

4. Robots as Competitive Advantages

In a competitive business environment, companies are always looking for ways to differentiate themselves. Robots provide companies with several strategic advantages that can give them a competitive edge:

4.1 Speed to Market

In industries like consumer electronics, fashion, and automotive, being the first to market with a new product can provide a substantial competitive advantage. Robots help companies speed up their production processes, allowing them to bring new products to market faster.

- Faster Prototyping and Testing: Robots in design and development stages speed up the process of product iteration, enabling businesses to quickly identify the best designs and produce prototypes.

- Efficient Production Lines: Once the product design is finalized, robots can quickly scale production to meet market demand, reducing time-to-market and ensuring the company stays ahead of competitors.

4.2 Cost Reduction and Profitability

While the initial investment in robotic systems can be significant, the long-term cost savings make them highly cost-effective. Robotics enables businesses to reduce labor costs, improve production efficiency, and minimize waste, which significantly lowers overall operational costs.

- Reduced Labor Costs: Robots perform tasks that would otherwise require multiple human workers, reducing labor costs and minimizing human error.

- Optimized Resource Usage: Robots are highly efficient in managing resources, whether raw materials, energy, or time. This leads to lower production costs and better profit margins.

4.3 Product Quality and Consistency

In markets where product quality is paramount, robots can help companies maintain consistent high standards. Their ability to perform tasks with extreme precision ensures that every product meets the same quality specifications.

- Improved Precision: Robots eliminate variability in product quality, ensuring consistent performance and reducing the need for rework or quality checks.

- Customization at Scale: Robots enable companies to customize products for individual customers while maintaining quality and efficiency, especially in industries like fashion, consumer goods, and automotive.

5. The Future: How Robots Will Shape Business Strategy

The role of robots in business is expected to expand further in the coming years, with the integration of advanced technologies such as AI, machine learning, collaborative robots (cobots), and IoT. These technologies will make robots even more capable and strategic in driving business success.

5.1 AI and Machine Learning Integration

The integration of AI and machine learning with robotic systems will further enhance their decision-making capabilities. Robots will be able to learn from data, adapt to new situations, and optimize production processes without human intervention. This evolution will lead to more intelligent robots that can handle tasks traditionally requiring human judgment.

5.2 Collaborative Robots (Cobots)

Cobots will play an increasingly significant role in manufacturing and other industries, working alongside human workers to improve productivity and safety. Cobots can perform tasks like material handling, assembly, and even customer service, allowing businesses to maximize their workforce’s potential.

- Enhanced Human-Robot Collaboration: Cobots will enable workers to perform more complex tasks with the assistance of robotic technology, allowing businesses to achieve better results without fully automating every process.

- Worker Safety: Cobots can take over dangerous tasks, reducing the likelihood of workplace injuries and enhancing overall safety in production environments.

5.3 Robotic Process Automation (RPA)

Robotic process automation (RPA) will play an important role in streamlining administrative tasks, such as data entry, customer service, and inventory management. RPA systems can automate repetitive tasks in back-office operations, freeing up human workers for more value-added activities.

6. Conclusion

Robots have evolved from mere tools on the production line to strategic assets that drive business success. By enhancing operational efficiency, driving innovation, increasing scalability, and offering competitive advantages, robots have become central to modern business strategy. As companies continue to integrate advanced robotics technologies, they will be able to further improve their production processes, adapt more quickly to market changes, and offer high-quality, customized products to consumers. In the future, robots will not only shape the way businesses operate but will redefine how businesses think about strategy, value creation, and long-term success.